RPC Crates vs. Single-Use: The Economics of Reusable Produce Packaging

The produce industry faces mounting pressure to reduce waste while maintaining profitability. As retailers and distributors evaluate their packaging strategies, the debate between reusable plastic containers and single-use packaging has become increasingly relevant. Understanding the true cost implications of each option is essential for making informed decisions that balance environmental responsibility with bottom-line performance.

The Hidden Costs of Single-Use Packaging

Single-use corrugated boxes and disposable containers may appear cost-effective at first glance, but the total expense extends far beyond the initial purchase price. Organizations must account for multiple factors that impact their operational budgets over time.

Every shipment requires new packaging materials, creating a continuous procurement cycle that drains resources. Labor costs associated with assembling boxes, disposing of damaged containers, and managing waste removal add up quickly. Additionally, single-use options often provide less protection for delicate produce, leading to increased product damage during transit and handling. When factoring in the environmental disposal fees and waste management costs many municipalities now impose, the true financial burden becomes apparent.

The Economic Advantage of Reusable Systems

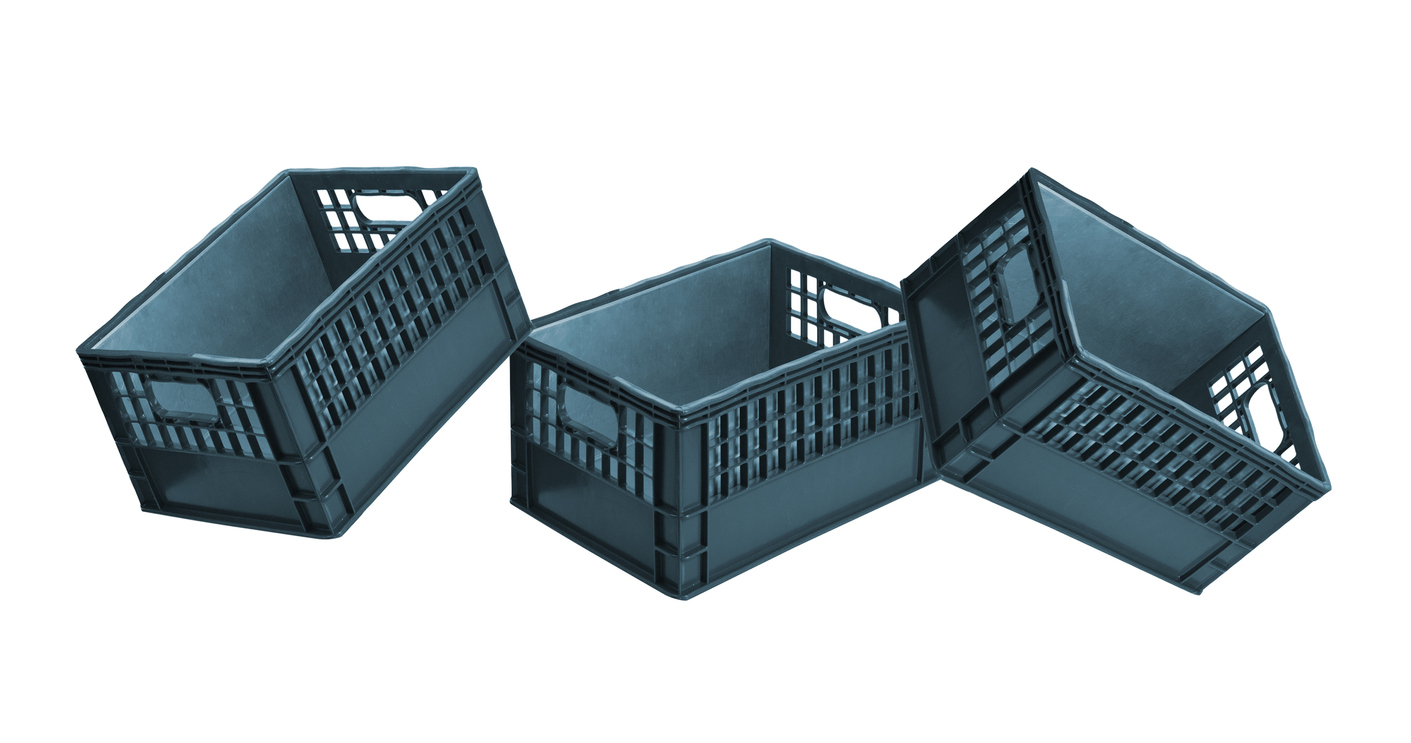

RPC crates represent a fundamental shift in how the produce industry approaches packaging economics. While the upfront investment is higher than disposable alternatives, the long-term savings become evident through extended use cycles and reduced operational expenses.

Key Financial Benefits Include:

- Durability and Longevity: Quality reusable containers withstand hundreds of trips, eliminating the need for constant repurchasing

- Labor Efficiency: Standardized designs streamline handling, loading, and unloading processes

- Product Protection: Superior structural integrity reduces bruising and damage, minimizing product loss

- Waste Reduction: Elimination of disposal costs and reduced waste management fees

- Supply Chain Optimization: Consistent sizing improves truck loading efficiency and warehouse space utilization

The break-even point for reusable packaging systems typically occurs within 12 to 24 months, depending on usage volume and distribution patterns. After this initial period, organizations experience significant net savings compared to ongoing single-use purchases.

Operational Efficiency and Supply Chain Performance

Beyond direct cost savings, reusable produce packaging delivers measurable improvements in supply chain performance. Standardized containers facilitate automation in sorting and distribution centers, reducing manual handling requirements and improving throughput speeds.

The structural consistency of these systems enables more efficient palletization, maximizing trailer capacity and reducing transportation costs per unit. Unlike corrugated boxes that weaken when exposed to moisture or temperature fluctuations, durable plastic containers maintain their integrity throughout the cold chain, ensuring produce arrives in optimal condition.

Inventory management becomes more streamlined with reusable systems. Distribution centers can predict container availability more accurately, reducing emergency packaging purchases and associated rush shipping fees. The elimination of flat storage space for empty single-use boxes frees up valuable warehouse real estate for revenue-generating inventory.

Environmental Considerations with Financial Implications

Corporate sustainability commitments are no longer purely altruistic—they carry tangible financial consequences. Retailers and food service operators increasingly require suppliers to demonstrate environmental responsibility through measurable metrics.

Environmental Benefits That Impact the Bottom Line:

- Reduced Carbon Footprint: Fewer raw material extractions and manufacturing cycles lower overall emissions

- Waste Diversion: Elimination of thousands of pounds of corrugated waste annually

- Water Conservation: Reusable systems require less water consumption compared to continuous paper production

- Regulatory Compliance: Proactive positioning ahead of potential packaging waste legislation

- Brand Value: Enhanced reputation with environmentally conscious customers and partners

Organizations that adopt sustainable packaging solutions often gain preferential treatment in procurement decisions. Many major retailers now include sustainability criteria in their vendor scorecards, directly linking environmental performance to business opportunities. The cost of not addressing these concerns may include lost contracts or reduced shelf space allocation.

Implementation Considerations

Transitioning to reusable packaging requires careful planning and partnership with experienced providers. Successful implementations account for container pooling logistics, cleaning and sanitation protocols, and reverse logistics systems to ensure empty containers return efficiently to distribution points.

Working with a knowledgeable packaging partner helps organizations navigate these complexities. The right provider offers not just containers, but complete system design, including tracking mechanisms, maintenance programs, and ongoing support to optimize container utilization rates.

Arena Products understands that every operation has unique requirements based on product types, distribution networks, and volume patterns. Whether you’re evaluating a pilot program or planning a full-scale conversion, expert guidance ensures your reusable packaging system delivers maximum return on investment while meeting food safety and quality standards.

Making the Transition

The shift from single-use to reusable packaging represents more than a simple substitution—it’s a strategic decision that impacts multiple aspects of your operation. Organizations that approach this transition methodically, with clear metrics and defined goals, position themselves for long-term competitive advantage.

Starting with a focused pilot program allows you to validate cost savings projections and refine handling procedures before full-scale implementation. This measured approach builds internal support and demonstrates tangible results to stakeholders.

The economics of reusable produce packaging continue to improve as more organizations adopt these systems, creating network effects that enhance container availability and reduce logistics complexity. Early adopters benefit from competitive differentiation while establishing operational practices that will become industry standard.

Contact us today to request a quote or speak with an expert!