Liquid Tote Liners: Maximizing Food and Beverage Hygiene

Food and beverage manufacturers face unprecedented scrutiny regarding product safety and hygiene standards, making the selection of appropriate packaging solutions a critical business decision. Liquid tote liners have emerged as an essential component in maintaining the highest levels of food safety while optimizing operational efficiency throughout the supply chain. These specialized barrier systems provide comprehensive protection against contamination while ensuring compliance with stringent regulatory requirements that govern food-grade applications.

As consumer awareness of food safety continues to increase and regulatory agencies implement increasingly stringent oversight measures, manufacturers must prioritize packaging solutions that deliver both superior hygiene performance and operational benefits. Liquid tote liners represent a proven technology that addresses these dual requirements, offering manufacturers the confidence to maintain product integrity from production through final delivery while streamlining their cleaning and quality assurance processes.

Understanding Liquid Tote Liners and Their Critical Role

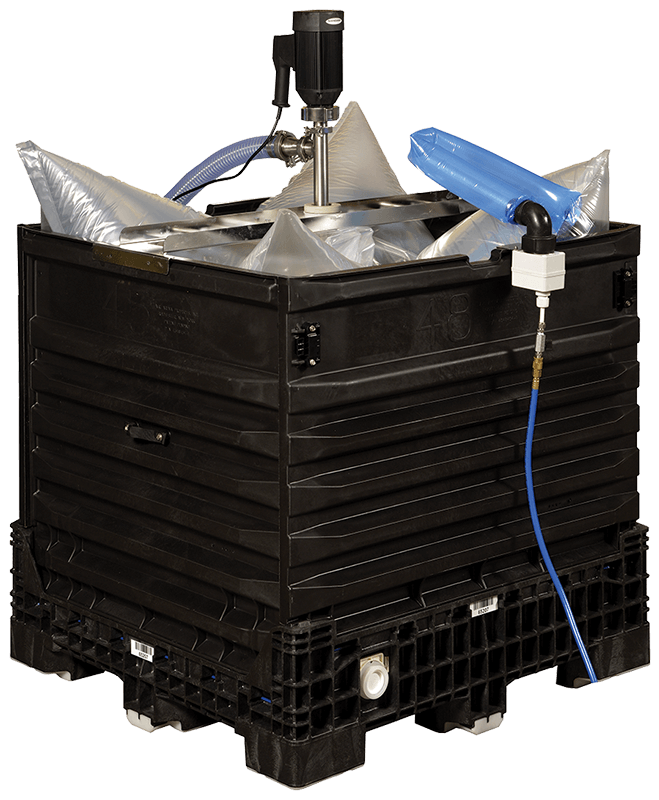

Liquid tote liners are sophisticated barrier systems designed to create a protective interface between liquid products and intermediate bulk containers (IBCs). These engineered plastic films serve as dedicated containment vessels, eliminating direct product contact with container surfaces and fundamentally transforming how food and beverage manufacturers approach hygiene management. The liners are manufactured using FDA-approved materials and advanced production processes that ensure consistent quality and performance across diverse applications.

The critical role of liquid tote liners extends beyond simple containment to encompass comprehensive prevention of contamination, regulatory compliance, and operational efficiency. These systems are engineered to withstand the rigors of industrial filling, transportation, and discharge operations while maintaining absolute product integrity. Arena Products has pioneered innovations in liquid tote liner technology that address the unique challenges faced by food and beverage manufacturers operating under strict hygiene protocols.

Modern liquid tote liners incorporate advanced materials science to deliver superior barrier properties against environmental contaminants, moisture, oxygen, and other factors that could compromise product quality. The engineering specifications include precise thickness tolerances, seam strength requirements, and chemical compatibility testing that ensures optimal performance across a wide range of liquid products. These technical capabilities make liquid tote liners indispensable for maintaining the sterile environments required in food and beverage production.

Contamination Prevention: The Primary Hygiene Benefit

The fundamental hygiene advantage of liquid tote liners lies in their ability to create an impermeable barrier between products and external contamination sources. This protection mechanism operates on multiple levels, addressing both visible contaminants and microscopic threats that could compromise product safety or quality. Traditional container cleaning processes, regardless of their thoroughness, cannot eliminate all potential contamination risks that accumulate over multiple use cycles.

Cross-contamination represents one of the most significant threats to food safety in multi-product manufacturing environments. Liquid tote liners eliminate this risk entirely by providing dedicated, single-use containment for each product batch. This approach ensures that residual flavors, allergens, or other product components cannot transfer between different manufacturing runs, even when using the same container infrastructure.

The contamination prevention capabilities of liquid tote liners extend to environmental threats encountered during transportation and storage. Our comprehensive liner systems provide protection against dust, moisture, temperature fluctuations, and other external factors that could compromise product integrity. This environmental protection proves particularly valuable for sensitive products that require strict environmental controls throughout their supply chain journey.

Barrier Protection Against External Contaminants

The barrier properties of liquid tote liners are engineered to provide comprehensive protection against a wide range of external contaminants. These include airborne particles, chemical vapors, moisture intrusion, and ultraviolet light exposure that could degrade product quality or introduce safety concerns. Advanced liner materials incorporate multiple layers with specific barrier characteristics optimized for different protection requirements.

Chemical resistance represents a critical aspect of barrier protection, particularly for manufacturers handling acidic or alkaline products that could interact with container surfaces. Liquid tote liners are made from materials that are chemically inert to food and beverage products, while maintaining structural integrity under various pH conditions and temperature ranges.

Preventing Product Cross-Contamination

The single-use nature of liquid tote liners provides absolute assurance against cross-contamination between different product batches or formulations. This protection proves invaluable for manufacturers producing multiple products that use shared equipment, where even trace amounts of previous products can create quality issues or regulatory violations. The clean changeover process enabled by liner systems eliminates the complex cleaning validation procedures required with traditional container cleaning approaches.

Allergen control is a particularly critical application for preventing cross-contamination. Liquid tote liners ensure that products containing common allergens cannot contaminate subsequent batches of allergen-free products, helping manufacturers maintain compliance with labeling requirements and protect sensitive consumers.

FDA Compliance and Food Safety Standards

Regulatory compliance in food and beverage manufacturing requires adherence to comprehensive standards governing materials, processes, and documentation. Liquid tote liners designed for food-grade applications must meet strict FDA requirements for direct food contact materials, including migration testing, toxicological evaluation, and manufacturing quality standards. Arena Products’ commitment to regulatory compliance ensures that our liner systems meet or exceed all applicable food safety standards.

The FDA’s Current Good Manufacturing Practice (cGMP) regulations establish specific requirements for equipment and container sanitation, which liquid tote liners help manufacturers efficiently satisfy. These regulations mandate that food contact surfaces be maintained in a sanitary condition, which liner systems achieve through their single-use design that eliminates concerns about cleaning effectiveness or residual contamination.

Documentation requirements for food safety compliance include maintaining detailed records of cleaning procedures, conducting validation studies, and documenting corrective actions. Liquid tote liners simplify this documentation burden by eliminating the need for complex cleaning validation protocols while providing clear audit trails through lot tracking and certificate of compliance documentation.

Material Safety and Certification Requirements

Food-grade liquid tote liners must demonstrate compliance with FDA regulations governing indirect food additives, including specific migration limits and safety testing protocols. These requirements ensure that liner materials do not introduce harmful substances into food products while maintaining their protective barrier properties throughout the intended use period.

Kosher and halal certifications represent additional compliance considerations for manufacturers serving specific market segments. Our manufacturing processes and materials are certified to meet the requirements of these specialized markets.

Operational Hygiene Benefits and Efficiency Gains

Beyond contamination prevention, liquid tote liners deliver significant operational benefits that enhance overall hygiene management while reducing costs and complexity. The elimination of container cleaning requirements represents the most immediate operational advantage, freeing personnel and resources for more value-added activities while ensuring consistent hygiene standards.

Labor efficiency improvements from liquid tote liners stem from simplified changeover procedures that require minimal time and technical expertise. Traditional container cleaning processes can require several hours and specialized training, while liner changeovers typically take minutes with standard operational personnel. This efficiency translates to increased production capacity and reduced labor costs.

Quality assurance benefits include consistent hygiene performance, which eliminates the variability associated with manual cleaning procedures. Liquid tote liners provide standardized protection that is independent of operator technique or cleaning equipment performance, ensuring consistent hygiene outcomes across all production batches.

The following operational advantages distinguish liquid tote liners from traditional cleaning approaches:

- Elimination of cleaning time and associated labor costs

- Reduced water and chemical consumption for cleaning operations

- Simplified quality assurance procedures and documentation

- Enhanced production flexibility through faster changeovers

- Reduced risk of cleaning-related equipment damage or wear

Our comprehensive approach to liner technology includes supporting equipment and procedures that maximize these operational benefits while ensuring optimal hygiene performance.

Best Practices for Maximum Hygiene Performance

Achieving optimal hygiene performance with liquid tote liners requires attention to proper installation, handling, and quality control procedures. Best practices begin with appropriate liner selection based on product characteristics, container specifications, and operational requirements. Different liner configurations offer varying advantages for specific applications, making proper selection critical for success.

Installation procedures must ensure proper liner positioning and secure attachment to prevent contamination during filling operations. Standard operating procedures should address:

- Pre-installation container inspection and preparation

- Liner positioning and attachment verification

- Filling procedures that maintain liner integrity

- Post-filling inspection and sealing protocols

- Documentation requirements for traceability

Quality control checkpoints throughout the process help identify potential issues before they impact product safety or quality. These include visual inspections, seal integrity testing, and lot tracking procedures that ensure full traceability from liner manufacture through product discharge.

Storage and handling practices for liquid tote liners must maintain their protective properties until they are installed. Our technical support resources provide detailed guidance on proper storage conditions, handling procedures, and shelf life management to ensure optimal performance.

Temperature control considerations become crucial for products that require specific thermal conditions during transportation or storage. Liquid tote liners maintain their barrier properties across typical food-grade temperature ranges while accommodating thermal expansion and contraction that occurs during temperature changes.

Enhance Your Food Safety Program with Arena’s Liquid Tote Liners

The compelling hygiene advantages of liquid tote liners make them an essential component of comprehensive food safety programs for modern food and beverage manufacturers. Arena Products brings over 40 years of experience in developing and manufacturing liner systems that meet the highest hygiene standards while delivering operational efficiency improvements that enhance profitability and competitive positioning.

Our proven track record in food-grade applications includes partnerships with leading manufacturers who rely on our liquid tote liners to maintain their quality standards while optimizing their operations. Contact our team today to learn how our advanced liner systems can improve your hygiene performance while reducing costs and operational complexity.