The Standard Of Performance In Collapsible, Plastic IBC’s

The Arena A330 Shipper™ outshines other bulk containers in performance and versitility. As a transportation solution, it is the most cost-effective, reusable alternative to other bulk liquid handling options.

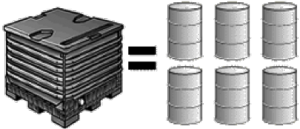

The Arena A330 Shipper™ Vs. 55 Gallon Drums

The Arena A330 Shipper™ produces marked gains in safety, efficiency and cost-savings versus traditional 55-gallon drums. Because the A330 is a larger volume container, a smaller number of them are required to move, fill and load product which reduces risk of mishap or accident. It’s integrated, forklift-friendly design eliminates the need for costly pallets. Handling and transportation are simplified because there is not need to shrink-wrap containers for stability as is often required for 55 gallon drums.

- One fully loaded Arena A330 Shipper™ holds the contents of six metal drums in the same space required for four drums.

- The A330 is a more efficient IBC with 78% of the external volume containing product.

- It hold up to 3,000lbs./330 gallons of non-hazardous bulk liquids and up to 4,000 lbs of bulk product.

- The A300 is a reusable tote designed for fast-turnaround, multiple use whereas many 55-gallon containers are single use products.

- The A330 design minimizes product waste as compared to 55-gallon drums which can collect product and make discharge more difficult.

- The A330 is made from recyclable plastics, making it more environmentally friendly since it reduces the cost and number of steel drums that are disposed of in the waste stream.

- The A330 allows for re-use without testing for extended periods and because it is specifically designed for liquid containment, it is less susceptible to handling damage than steel drums.

- Quality control and inventory management enjoy increased efficiencies because the A330 allows for easier logistics tracking and container usage history.

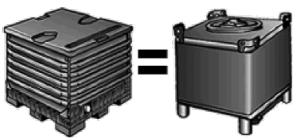

The Arena A330 Shipper™ Vs. Stainless Steel IBC

- Lower initial investment for the Arena A330 Shipper™ than more expensive stainless steel tanks

- Lower tare weight of A330 results in reduced outbound shipping costs

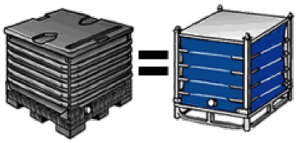

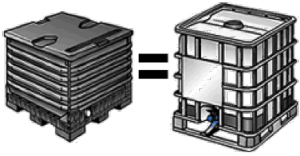

- Significant reduction in return shipping costs because stainless steel totes are a fixed design while the A330 IBC is collapsible and more space efficient.

- Cleaning, reconditioning and effluent disposal costs associated with stainless steel tanks are eliminated by the A330.

- Risk of contamination is reduced because the A330 is equipped with a liner bag that provides an added level of product protection.

- Replacement plastic parts are more economical and reduce maintenance costs.

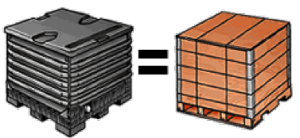

The A330 Shipper™ vs. Plywood Bag-In-Box

- The plastic composite construction of the A330 delivers a much longer product life versus plywood containers.

- The A330 is easier to set-up and knock-down, reducing operator handling costs.

- The A330 is superior to plywood IBC’s because it is easier to clean which improves sanitation and reduces risk of contamination and insect infestation.

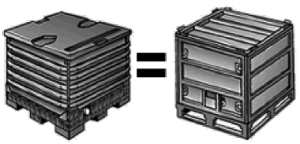

The A330 Shipper™ Steel Frame Rigid Wall Knockdown Bag-In-Box

- Lower tare weight of A330 reduces shipping costs.

- Cost of ownership or rental is significantly lower for the A300 Shipper™.

- Plastic composite construction of A330 makes cleaning easier with reduced maintenance costs.

- Plastic construction eliminates hazards associated with rust and corrosion that can occur with steel frames.

The A330 Shipper™ Vs. Steel Frame Flexible Knockdown Bag-In-Box

- Reduced set-up and knockdown labor costs for the A330.

- A330’s lower tare weight means lower outbound shipping costs.

- The A330 is easier to clean with reduced maintenance costs

- Rigid plastic container walls of the A330 provide greater product protection during handling, storage and transportation.

- Cost of ownership and rental is significantly lower for the A330.

- Issues with rust or corrosion are eliminated by the all-plastic construction of the A330.

The Arena A330 Vs. Corrugated Bag-In-Box

- A330 renders much lower packaging cost.

- Eliminates need to landfill 80 lbs of corrugated waste.

- Corrugated requires additional pallet versus integrated pallet design of A330.

- A330 is cleanable and reduces risk of contamination and insect infestation.

- Reduced labor costs for set-up and knockdown of the A330.

- Plastic composite construction of the A330 is not subject to water or high humidity damage that is a concern for corrugated.

The A330 Vs. Bottle-In-A-Cage Intermediate Bulk Container

- Packaging costs are markedly lower for the A330.

- A330 Shipper™ delivers a longer life span.

- Lighter weight and collapsibility design lowers freight costs.

- A330 utilizes a virgin liquid liner each trip which protect product integrity by minimizing risk of contamination.

- Recyclable plastic composition of the A330 greatly reduces solid waste and disposal labor if the intermediate bulk container is not reused.

- Lower cleaning, inspection, maintenance and repair costs for the A330.